In brief

Presentation

Are you ready to shape the future of the polymers manufacturing industry?

Our Master’s program in "Processes and Polymers" is your gateway to an exciting and fulfilling career in one of the most dynamic fields today. This program is designed to align with the latest industry trends in energy efficient processes, bioplastics manufacturing and plastics recycling. It will equip you with the knowledge and skills needed to excel in polymer processes engineering.

Training objectives

Imagine a world without polymers - our cars, clothes, and homes - would be unrecognizable. Polymers are the backbone of countless advances in medicine, construction, energy, electronics, and consumer goods. The ever-evolving polymer industry thrives on innovation, constantly pushing the boundaries to develop lightweight materials with required properties to meet customer demands.

Our Processes and Polymers Master’s program offers you an unparalleled opportunity to dive deep into this dynamic industry. Gain comprehensive knowledge and hands-on experience across the entire petrochemical chain, from diverse resources to the final plastic products. You’ll be trained in every critical step: refining processes, base chemical production, industrial polymerization, and plastic processing.

We place a strong focus on technical skills in chemical engineering and in project management for the development, design and operation of safe and clean processes. The program is continuously adapting to the main industry trends, especially on environmental concerns, therefore includes courses related to plastics life cycle assessment and management, and bio- sourced polymers.

You’ll engage in hands-on learning through industry projects, multiple field trips and internships with leading companies. Courses are taught by a distinguished faculty, who bring their extensive industry experience and cutting-edge research into the classroom. Up-to-date pedagogical methods like e-learning, micro-learning and serious games, have been introduced to ensure that all students have the same background knowledge before the course, while real-time quiz stimulate interaction between you and the lecturers.

Additionally, our program emphasizes soft skills development, including leadership, project management, and communication, ensuring you are well-prepared to take on leadership roles in your future career. Our strong connections with industry partners provide unparalleled networking opportunities, internships, and job placements. You’ll be part of a diverse, international community of students and alumni, fostering a global perspective and collaborative spirit.

After the Processes and Polymers program, in a sector stimulated by the development of new applications, you will be offered career opportunities in process development and optimization, product development, project engineering, operations and sales.

Typical class profile

Students in this program are almost all supported by companies through an apprenticeship contract or a scholarship to help finance their living expenses.

Main partners

Among these companies, the following have been IFP School partners in recent years (non-exhaustive list):

- Arkema

- Axens

- Bostik

- ExxonMobil

- IFPEN

- Ineos

- Infineum

- Lyondell Basell

- Michelin

- Plastic Omnium

- S-Oil

- Technip Energies

- TotalEnergies...

The key points of the program

Career prospects for graduates

Program & planning

Program content

Chemical engineering fundamentals, operation, and safety management

- Separation processes

- Design and operational issues of main equipment: heat exchangers and rotating machinery

- Polymer reaction engineering

- Risk management and process operation safety

Basic and detailed engineering

- Chemical reactor technologies design and operation

- Engineering projects in petrochemistry: PFD & PID, project cost estimation and management

- Production planning & supply chain of a polyolefins site

Processes

- From Oil and Gas to Hydrogen processes

- Base chemicals, main hydrocarbons intermediates and monomers

Plastics chain value

- Plastics chain value & manufacturing

- Overview of plastic processing

- Recycling processes

Innovative and Sustainable chemicals

- How to create a new process ever more sustainable (eco- design)

- Bio-sources markets & bio-polymers processes

- Environmental impact of polymers through life cycle assessment (LCA)

Experience sharing module

Development of soft skills

📌 Elective path1: Plastics chain value

- Plastic chain value & manufacturing

- Overview of plastic processing

- Recycling processes

📌 Elective path2: Innovative and Sustainable chemicals

- How to create a new process ever more sustainable (ecodesign)

- Biosources markets and Bio-polymers processes

- Environmental impact of polymers through Life Cycle Analysis

Schedule

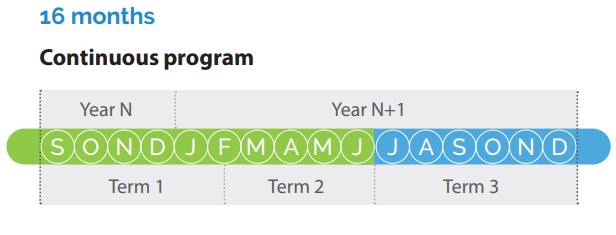

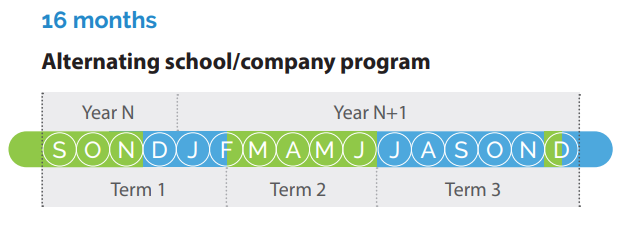

The two examples of schedules shown below correspond to the most frequently encountered cases for students in this program:

- 16-month continuous program for students with a 4- or 5-year engineering degree;

- alternating school/company 16-month program for students with a 5-year engineering degree.

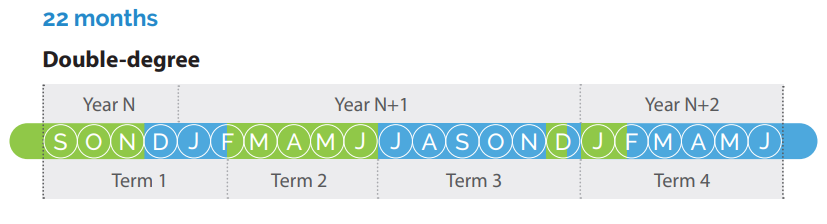

There are other possible cases, such as:

-

a 22-month alternating school/company program for students in their penultimate year of a major European school or university having signed a double-degree agreement with IFP School

Career opportunities

- Process development and optimization

- Product development

- Engineering

- Energy optimization

- Operations and HSE management

- Logistics and sales