The use of virtual reality at IFP School is not new. For several years now, the educational teams have been developing modules based on 360° photographs taken on site: engine benches, industrial sites, geological fields, etc. This work was recognized during the 2017 Digital Learning Excellence Awards organised by the CEGOS: the School was awarded the jury's grand prize for its "Inspecting an industrial unit" training device, in which virtual reality was used to prepare for real-life situations.

Virtual reality, an educational catalyst

Offering real-life experience to students can be a challenge in today’s world. Organising visits to industrial sites in France or abroad means dealing with issues such as facility confidentiality, risk management, visa management, expenses… Hence, the natural move towards integrating virtual reality in our teaching programs. VR is now widely recognized as an interesting "hands-on" learning tool. In addition to its pedagogical advantages – skills are acquired through "learning by doing", the emotions generated during the actual experience ensures that the acquired knowledge is anchored in students’ memories, etc. – virtual reality appears to be a real educational catalyst for IFP School.

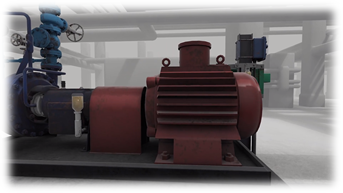

This is why, at the beginning of 2020, the School launched the VR Industrial Pump project: the objective was to develop the first "Full 3D" virtual reality module (see visuals). This module is part of the curriculum of students in the Energy & Processes and Processes & Polymers programs. It aims at ensuring students can apply a pump’s start-up procedure as well as the procedure for swapping one pump for another, two tasks previously only covered in lectures.

|

|

|---|---|

|

On the left: visualization of a 360° virtual reality module (made from a 360° photograph on which interactive elements are inlaid). |

|

Return on the design of the VR project Industrial Pump

We needed a 360° virtual reality module, that could not simply be created from 360° photographs and editing software, so we retained a service provider with 3D design skills. We contacted Numix, a company based near Toulouse that we had met at "Laval Virtual", one of the largest virtual reality trade shows in the world. At the time, we had been impressed by their products and services and, in particular, their teaching tool that allows a trainer to monitor and receive quality feedback on the actions performed by his/her trainee, on the fly. This is an undeniable asset when you know how difficult it is for a trainer to include virtual reality in a training course.

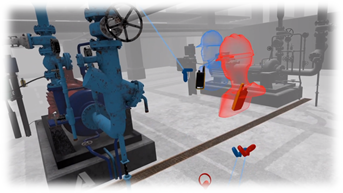

After some initial discussions and having defined the module's specifications, we worked with Numix to develop a script and a module that met our expectations from an educational point of view. Icing on the cake, Numix decided to make the most of this project to improve its offering and develop a particularly interesting new feature: the multi-user mode. This mode allows several users to interact with each other while being fully immersed in a virtual environment: particularly handy for trainers who can now follow all their trainees in the virtual world, exchange with them and question their understanding of the actions being carried out. This feature offers multiple future educational options: students accompanied by a trainer in total immersion, several trainees wishing to practice on their own, or several trainers wishing to learn how to use educational virtual reality tools (teach the trainer programs).

|

|

|

|

A teacher (in blue) shows a student (in red) where the pump's discharge valve is located. |

From conception to implementation

Once the module had been validated, from both a technical and pedagogical point of view, a hands-on course was organized with students. They first had to follow an asynchronous training module dedicated to the theme of starting and switching two pumps. Then over two days, more than 60 students were given the opportunity to use the VR Industrial Pump module synchronously at the School. The pedagogical objectives of these two sequences were as follows:

- Identify the components of a centrifugal pump;

- Start a centrifugal pump;

- Swap two centrifugal pumps in order to make one of them available for maintenance.

From the trainer's point of view, the implementation of this teaching sequence proved to be particularly demanding. In addition to the educational progression of the sequence, it was necessary to manage the technological aspects of the lesson: connecting the headsets to a local network to enable the multi-user mode, explaining how the equipment was operated (headsets and controllers), managing operating errors and other technical breakdowns (lack of batteries), etc. Despite the presence of a second trainer, the exercise proved complex on the first few passes! However, the learning curb was short and after two or three runs, the right processes were found.

With hindsight, certain actions could have been put in place prior to the workshops to allow the teacher to focus on his teachings, without having to worry about the technical aspects as well as invite the student to concentrate on the actions to be carried out rather than on how to use the material. The following actions or points of improvement were identified:

- Producing a video tutorial for the pupils, so that they understand the operating principle of the equipment before their VR experience. This could be shown, for example, 10 minutes before the start of the workshop;

- Drawing up a technical FAQ so that the teacher can quickly identify any technical issues (e.g. disconnection) and address it without affecting the immersion experience of the other participants;

- Preparing an introductory activity to the VR module to help students become more familiar with the technology;

- Using technology that is more user-friendly.

|

|

|

|

Three students perform a start-up procedure in virtual reality. |

||

Feedback that paved the way for IFP’s future virtual reality laboratory

The future virtual reality laboratory, due to open its doors in the first half of 2021 at IFP School, will spearhead the use of user-friendly VR technology: 90 square metres entirely dedicated to immersive tools & technology, and designed to facilitate their use in a teaching context.

Even if it is currently difficult to quantify the impact of this virtual reality experience on students' ability to take in procedures, the learners' self-evaluation shows a very positive satisfaction rate:

- 86% of trainees said they had learnt procedures better thanks to their virtual reality experience rather than by covering it in a lecture;

- 97.7% of students were convinced by the multi-user mode and its educational benefits;

- More than 90% of students reported having:

- An excellent/good learning experience;

- Excellent/good teaching effectiveness;

- Excellent/good user comfort;

- An excellent/good user experience.

In addition to helping students learn and apply technical skills, this unique opportunity equally enabled them to develop non-technical skills - "soft skills" - thanks to the multi-user mode. Trainees had to talk to each other, think together, collaborate, make decisions collectively and suffer the consequences together: a good simulation of what awaits them in the real world!

On the trainers' side, we also learnt a lot about this teaching mode and its use. When we started the training, all this technology was considered slightly frightening, but once mastered, we almost forgot it and simply helped students carry out their tasks as if we were in the real world. We interacted and exchanged with them as we would have done out in the field. Over the years, a teacher’s role has evolved: we have moved from having a transmissive role where the "knower" passed on his knowledge to the "learners", to working in a more co-developing mode in which the teacher accompanies the learner. The teacher guides students in their reasoning and stimulates their thought process through questioning. Students are in constant interaction with their trainer. This is a constructivist vision of learning.

This first full-3D module enabled us to highlight the advantages of such teaching methods, to evaluate the key role of certain features (such as the multi-user mode), but also to highlight the difficulties that needed to be overcome by both learners and teachers! Other modules of this type are currently being developed and will be integrated into the students' learning paths next year. The creation of the virtual reality laboratory will enable us to go even further in making IFP School a school resolutely focused on the acquisition of know-how and soft skills!

Author of the article : Clément Cahagne, Lab e•nov